You have no doubt heard the expression, "You get what you pay for". This phrase is absolutely true when it comes to tarps. Here we show a collection of tarps that are all less than five years old. You can see they all suffer from various failures which are quite common. You can click on any of the images below to see a detailed view of the tarp failure.

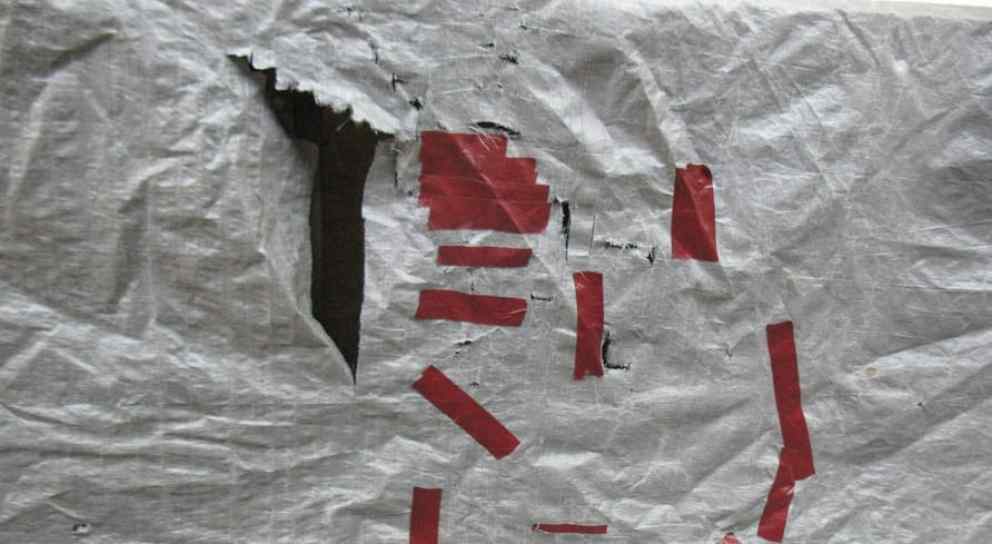

If anything sharp comes in contact with a polypropylene tarp it is most likely going to tear. This one was purchased from Princess Auto and repaired many times with duct tape but it is now too far gone. This particular tarp had a very short life because it was purchased to cover a utility trailer on a trip from Ontario to Nova Scotia. Within its first week of service it was full of holes from being blown around in the wind. Our tarps are made of thick vinyl which is very difficult to rip or tear.

If anything sharp comes in contact with a polypropylene tarp it is most likely going to tear. This one was purchased from Princess Auto and repaired many times with duct tape but it is now too far gone. This particular tarp had a very short life because it was purchased to cover a utility trailer on a trip from Ontario to Nova Scotia. Within its first week of service it was full of holes from being blown around in the wind. Our tarps are made of thick vinyl which is very difficult to rip or tear. This tarp was actually pretty heavy duty for a polypropylene tarp. The main surface held up well but the failure was in the edging. Cheap tarps either do not have any reinforcement in the edging or they just double up the material or have a string running along the edge like this one. In this case, tension on the grommet from the wind caused the edging to separate from the rest of the material. Our tarp's edges are reinforced with 6,000 pound seat belt material which is virtually impossible to rip off.

This tarp was actually pretty heavy duty for a polypropylene tarp. The main surface held up well but the failure was in the edging. Cheap tarps either do not have any reinforcement in the edging or they just double up the material or have a string running along the edge like this one. In this case, tension on the grommet from the wind caused the edging to separate from the rest of the material. Our tarp's edges are reinforced with 6,000 pound seat belt material which is virtually impossible to rip off. Here we have a side-by-side comparison of a tarp from Canadian Tire (on the left) and one of our 18 Oz vinyl tarps. You can completely see through the cheap tarp while the vinyl tarp on the right is opaque. The light weight nature of these tarps is one of the reasons that they don't last. This also makes it easy for the wind to catch them which causes pulling on the grommet fasteners. Our tarps have sufficient weight so that it takes a pretty strong wind to move them.

Here we have a side-by-side comparison of a tarp from Canadian Tire (on the left) and one of our 18 Oz vinyl tarps. You can completely see through the cheap tarp while the vinyl tarp on the right is opaque. The light weight nature of these tarps is one of the reasons that they don't last. This also makes it easy for the wind to catch them which causes pulling on the grommet fasteners. Our tarps have sufficient weight so that it takes a pretty strong wind to move them. If you have owned a poly tarp for any length of time, chances are that it is missing some grommets. These are very weak so it does not take much stress to have them pull off. Once a grommet is lost you need to avoid using this hole as a tie-down point because this tends to be a point of failure. Eventually you don't have sufficient grommets to tie the tarp down and it needs to be thrown in the garbage.

If you have owned a poly tarp for any length of time, chances are that it is missing some grommets. These are very weak so it does not take much stress to have them pull off. Once a grommet is lost you need to avoid using this hole as a tie-down point because this tends to be a point of failure. Eventually you don't have sufficient grommets to tie the tarp down and it needs to be thrown in the garbage. This tarp started to shred along the edge after a few years of use. The problem was most likely caused by prolonged exposure to the sun. The sun's UV rays cause the tarp material to break down which led to the shredding of the edge. Our heavy duty tarps include a UV coating for prolonged durability under direct sunlight.

This tarp started to shred along the edge after a few years of use. The problem was most likely caused by prolonged exposure to the sun. The sun's UV rays cause the tarp material to break down which led to the shredding of the edge. Our heavy duty tarps include a UV coating for prolonged durability under direct sunlight. Your light-weight tarp doesn't do you much good once it has blown off whatever you are trying to protect and it is sitting in your neighbour's back yard. Our tarps have a substantial weight to them so it takes a pretty significant wind to move them. When you use our free quote form we will provide you with an estimated weight for the size of tarp that you require.

Your light-weight tarp doesn't do you much good once it has blown off whatever you are trying to protect and it is sitting in your neighbour's back yard. Our tarps have a substantial weight to them so it takes a pretty significant wind to move them. When you use our free quote form we will provide you with an estimated weight for the size of tarp that you require. The seams on typical cheap tarps are not very strong and often fail if the tarp is being used to carry weight. All of our seams are "heat welded", not glued or stitched. This means that the vinyl material is actually melted onto itself. This process requires more manufacturing time and it ensures that the seams are extremely strong as well as being fully waterproof.

The seams on typical cheap tarps are not very strong and often fail if the tarp is being used to carry weight. All of our seams are "heat welded", not glued or stitched. This means that the vinyl material is actually melted onto itself. This process requires more manufacturing time and it ensures that the seams are extremely strong as well as being fully waterproof.So, you see, the problem with cheap tarps is that it is not only the price that is cheap but also the quality. In the end, you are better off investing in a high quality heavy duty tarp that will last for many years rather than just a few months.