Customers often contact us about ordering a very large tarp without fully considering whether the tarp they require is feasible for their application. Our main product line is heavy duty vinyl tarps that weigh 18 oz per square yard. Suppose you have a leaky roof and you can't get it repaired right away. A good option would be to cover this with a heavy duty tarp for a period of time to protect your home from damage. In fact, you should be aware that you have an obligation to mitigate damage as soon as you discover a leak in your roof. If you fail to do so, your insurance company may not cover any "secondary" damage that occurs after the leak was initially discovered.

Let's say the size of tarp you require is 40' x 60', such a tarp would weight about 312 pounds in 18 oz vinyl. If it is not feasible to lift a tarp of this weight onto your roof, you might need to consider a lighter weight material. It should be noted that you might be able to get a 312 pound tarp onto your roof without lifting it in its entirety. One way would be to tie rope onto several of the tarp's grommets on one edge and have, say, three people raise the roped edge of the tarp from the ground in unison. This way, each person would only be lifting 1/3 of the weight of the tarp and even less if some of the tarp is still sitting on the ground when the upper edge reaches the roof.

Let's say the size of tarp you require is 40' x 60', such a tarp would weight about 312 pounds in 18 oz vinyl. If it is not feasible to lift a tarp of this weight onto your roof, you might need to consider a lighter weight material. It should be noted that you might be able to get a 312 pound tarp onto your roof without lifting it in its entirety. One way would be to tie rope onto several of the tarp's grommets on one edge and have, say, three people raise the roped edge of the tarp from the ground in unison. This way, each person would only be lifting 1/3 of the weight of the tarp and even less if some of the tarp is still sitting on the ground when the upper edge reaches the roof.

You can use the free quote form on our website to determine the weight of any custom tarp. For the 40' x 60' tarp described above we can recalculate the weight using 14 oz vinyl which ends up weighing 244 pounds. If this is still too heavy for your application you could consider a poly tarp instead. This won't last as long but may be sufficient if you are only planning to cover your roof for a few months. Our best poly tarp is a 6oz tarp. In this material a 40' x 60' tarp will weigh 100 pounds. Astute readers may be wondering why this 6 oz tarp does not weigh 1/3 the weight of our 18 oz tarp. The reason is that poly tarps are always reported in "cut sizes" not "finished" sizes. Therefore, this tarp will end up being about 3 - 5% smaller than the size stamped on the package. Another reason that it will weigh less is that our 18 oz tarps have borders that are reinforced with seatbelt material which will add a bit of extra weight not found in the 6 oz tarp.

Suppose 100 pounds is still too heavy, our next option would be a 3.5 oz poly material in which a 40' x 60' tarp will weigh 58 pounds. While this is likely good enough for a few months, there is a lot more risk involved when using a lightweight tarp. The biggest risk involves high wind conditions. Strong winds causes a light tarp to blow uncontrollably which will create sufficient force on the grommets to rip them off the tarp. This is especially true is air if allowed to get under the tarp. Therefore, whenever you are using a lightweight tarp in a windy area always try to wrap the tarp completely around whatever it is covering to prevent wind from billowing the tarp. The second problem with light duty tarps is that they tear easily when dragged over sharp edges.

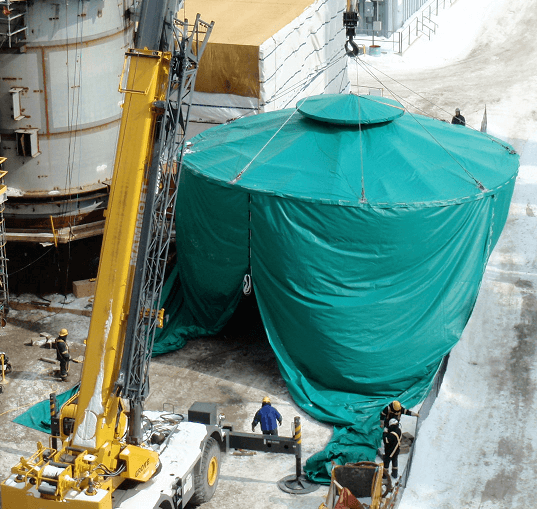

If you have the right equipment available to deal with a heavy tarp then its weight is less of an issue. A fork lift or a back hoe is often needed to move heavy tarps on and off of transport vehicles. On the job site, a crane may be required to raise heavy tarps onto where they need to be.

If you don't have suitable equipment to manage very large tarps, often your best option is to create several smaller tarps instead. If the tarps are used to keep the rain off a building or equipment, you will want to overlap the tarps using D-Rings set in on one edge of the tarp. These D-Rings can be fastened to grommets on the edge of the adjacent tarp. Always orient the tarps so that rain water will flow from one tarp to the next without seeping between the tarps.

If you are hanging a large tarp from one end, always consider the weight of the tarp and the load on each grommet. Suppose your tarp weighs 800 pounds and it is being supported by 40 grommets. In such a case, each grommet needs to support a minimum load of 20 pounds. If wind is blowing on this tarp, this could easily increase this load to 50 or 60 pounds per grommet. Adding more grommets is a good idea to reduce the load on each grommet however this often shifts the point of failure from the grommets to the hem itself. To reduce the stress on the hem when hanging very heavy tarps it is generally recommended to reinforce the tarp vertically using rows of seat belt material. Here we show a mesh tarp that has been reinforced every three feet. It is a good idea to add D-rings along this reinforcing, particularly near the upper edge of the hanging tarp. These extra D-rings can be secured to help distribute the load and reduce the likelihood that the hem will tear off from the weight of the tarp.

If you are hanging a large tarp from one end, always consider the weight of the tarp and the load on each grommet. Suppose your tarp weighs 800 pounds and it is being supported by 40 grommets. In such a case, each grommet needs to support a minimum load of 20 pounds. If wind is blowing on this tarp, this could easily increase this load to 50 or 60 pounds per grommet. Adding more grommets is a good idea to reduce the load on each grommet however this often shifts the point of failure from the grommets to the hem itself. To reduce the stress on the hem when hanging very heavy tarps it is generally recommended to reinforce the tarp vertically using rows of seat belt material. Here we show a mesh tarp that has been reinforced every three feet. It is a good idea to add D-rings along this reinforcing, particularly near the upper edge of the hanging tarp. These extra D-rings can be secured to help distribute the load and reduce the likelihood that the hem will tear off from the weight of the tarp.

Despite these precautions, it is still possible that hems or grommets can fail given enough weight and wind load. Therefore, you should avoid suspending a heavy tarp where it could fall on workers or bystanders.

When dealing with large tarps on a job site, you should generally have an engineer on site to make sure adequate safety precautions are being followed.